Our Expertise

CFD

With proficiency in numerical modelling, our CFD core team can offer our clients solutions to intricate fluids and fluid-structure interaction (FSI) problems from early stages of design to the end product thereby enabling our clients to better comprehend their product designs and optimise the energy efficiency.

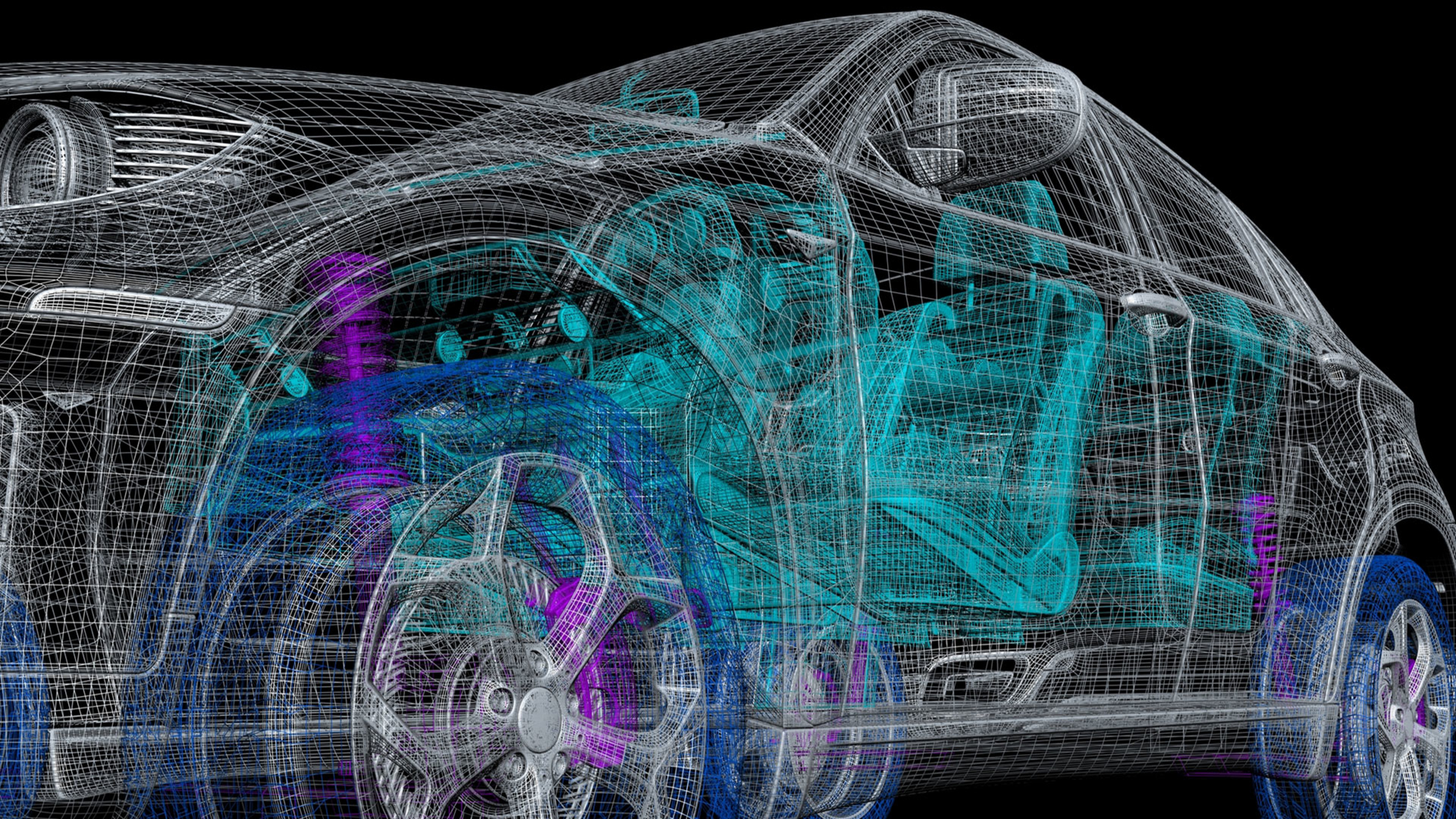

FEA

Our FEA analysis assists companies to assess their complex static and dynamics structures for integrity and performance which in turn provides safety and reliability assurance thereby improving the durability of the system and profitability by reducing the materials used.

Entrust us your engineering challenges and our experts will uncover the roots of the issues that are impacting your product development and quality control processes via our numerical and analytical analysis. At AERONAD+, we simulate your dreams using the most advanced technologies in the modelling arena with ANSYS being our pivotal simulation software.

Our Approach

WE ANALYSE

WE SIMULATE

WE DELIVER

Step 1

We start by undertaking a requirement elicitation process to know what problems to be solved and acknowledge the system boundaries set by the client, that is, their wish list. A requirement analysis process is then carried out thereby building an understanding about the characteristic of problem domain to recognise the actual requirements together with dependencies between them, that is, distilling the wish list for optimal performance according to the client’s demands. Our experts will then be in a position to propose a plan taking into account resources, time and cost factors, that is, setting up milestones for the project.

Step 2

We tackle the problem based on the agreement made and let you appreciate a virtual real-world environment to test your product designs using our state-of-art CFD and FEA technologies. Interim reports will be provided from time to time for adequate follow-up.

Step 3

An all-inclusive report which consists of the solutions acquired explained explicitly based on the drawings, models and the results generated, is documented and delivered within the agreed timeframe. Our engineers will also suggest propositions for enhancement of the design under study, where applicable. To be noted that all intellectual property rights belong to the clientele.

Whether you need a small design validation task analysed or a major research and development project completed, AERONAD+ is determined to exceed your expectations.